Over the year's I've dabbled in rapid prototype (RP) through a variety of sources. The best machines I've seen in use are still Perfactory. And they can create near perfect RP models without major layering issues. The build volume is small, so you're not going to get a full HO passenger car out of a machine. The price tends to be a bit higher as well. One of the first to get a machine and use it for models was Mark4Designs in New Zealand, and they printed some early stuff in N and Z scales going back to the mid 2000's.

In searching out other stateside sources for Perfactory RP machines, I ran across Best Cast in NJ. (www.best-cast.com)

Best Cast is a jewelry firm, but they have the machine and the capability. If you can send a solid model to them, they can probably print it. But the even better news is that they can convert the RP model to brass right away! Or they can mold off the RP, shoot wax, and do a run of brass parts.

I could picture lots of use for this for HO freight car details. Here's some examples I've completed with them so far.

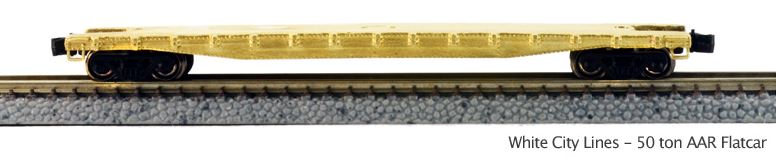

This is a Z scale 50 ton AAR Flat Car body. Yes, the Perfactory machine was able to hold tolerance on the lines of Z scale rivets. I did have to go back and forth with BestCast a couple of times to impress on them the need to accommodate for shrinkage of the brass properly, but they were able to produce a run of 100 beautiful copies of these cars for me. The body is all one piece, including the open stirrups, which wouldn't be doable in other production methods. A laser cut wood deck was all that was needed to finish the models.

Another example showing the fine detail that was possible were some hand hole bases for N scale searchlight signals.

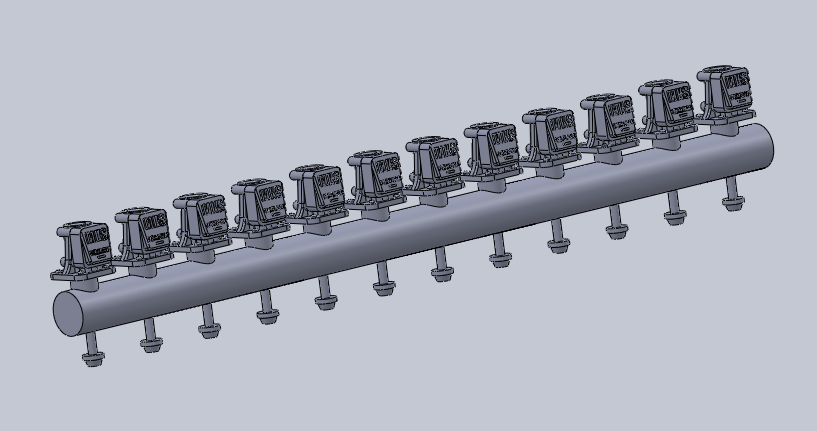

These were the Solidworks solid models.

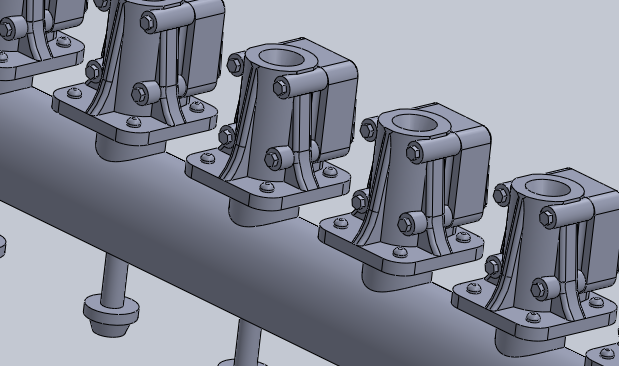

And these were the final parts produced by BestCast. Again, detail was possible here that couldn't be done with a simple a-b injection mold. And with the brass parts, the entire signal assembly could be soldered together.

Maybe there's a brake wheel, or various door stops/brackets/etc that would be good to have in durable, detailed brass castings. If you can create a digital solid model, BestCast or another jewelry firm may be able to help you out on production.

In searching out other stateside sources for Perfactory RP machines, I ran across Best Cast in NJ. (www.best-cast.com)

Best Cast is a jewelry firm, but they have the machine and the capability. If you can send a solid model to them, they can probably print it. But the even better news is that they can convert the RP model to brass right away! Or they can mold off the RP, shoot wax, and do a run of brass parts.

I could picture lots of use for this for HO freight car details. Here's some examples I've completed with them so far.

This is a Z scale 50 ton AAR Flat Car body. Yes, the Perfactory machine was able to hold tolerance on the lines of Z scale rivets. I did have to go back and forth with BestCast a couple of times to impress on them the need to accommodate for shrinkage of the brass properly, but they were able to produce a run of 100 beautiful copies of these cars for me. The body is all one piece, including the open stirrups, which wouldn't be doable in other production methods. A laser cut wood deck was all that was needed to finish the models.

Another example showing the fine detail that was possible were some hand hole bases for N scale searchlight signals.

These were the Solidworks solid models.

And these were the final parts produced by BestCast. Again, detail was possible here that couldn't be done with a simple a-b injection mold. And with the brass parts, the entire signal assembly could be soldered together.

Maybe there's a brake wheel, or various door stops/brackets/etc that would be good to have in durable, detailed brass castings. If you can create a digital solid model, BestCast or another jewelry firm may be able to help you out on production.